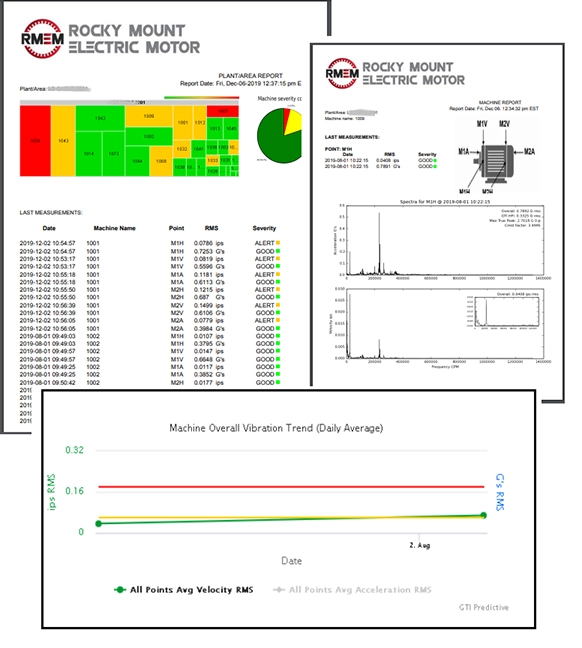

Vibration Analysis

Vibration Analysis is used to detect early precursors to machine failure, allowing machinery to be repaired or replaced before an expensive failure occurs.

Laser Alignment

The objective of optimized shaft alignment is to increase the operating life span of rotating machinery. Correct shaft alignment ensures the smooth, efficient transmission of power from the motor to the driven equipment. Misalignment produces excessive vibration, noise, coupling and bearing temperature increases, and premature bearing, coupling, or shaft failure.

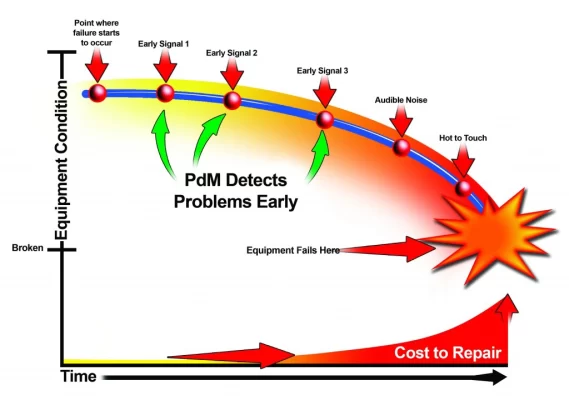

Predictive Maintenance

Proper motor maintenance goes a long way toward saving in the long run. Through the varied services that our experienced technicians provide, electric motors of various sizes, models, and makes receive the proper maintenance required to keep them running.

Motion Amplification

Utilizing the latest technology in motor analysis, motion amplification allows us to see the finest of details for motor assessment and repair. This technology turns every pixel into a sensor capable of measuring vibration or motion with high levels of accuracy. Capable of discovering issues that have plagued you that would otherwise be unseen, motion amplification allows you to discover the root cause of your motor troubles.

Lubrication Services

Are your bearings being lubricated properly? We often get these questions; how often should I lubricate my bearings and how much should I lubricate them? Take the guesswork out of this situation. With our lubrication services, our trained technician visits your facility on a prescribed time table and lubricates your equipment for you. We use ultrasound technology to assess the current condition of the bearing, then we add the exact right amount of grease. We provide you with a report showing each piece of equipment serviced, the type and amount of grease, and an indication of the health of the bearing.

Are your bearings being lubricated properly? We often get these questions; how often should I lubricate my bearings and how much should I lubricate them? Take the guesswork out of this situation. With our lubrication services, our trained technician visits your facility on a prescribed time table and lubricates your equipment for you. We use ultrasound technology to assess the current condition of the bearing, then we add the exact right amount of grease. We provide you with a report showing each piece of equipment serviced, the type and amount of grease, and an indication of the health of the bearing.

- We will meet with you and develop a program for your facility to meet your needs and budget.

- You can determine what type of equipment you want included and the initial interval.

- Once a plan is determined our trained technician comes to your facility and greases the agreed upon equipment on the agreed upon schedule.

- You will be provided a report following each service detailing the equipment greased, the type of grease used, the amount of grease applied and indication of the result.

- After repeated services, intervals can be increase to be sure units are greased when needed or reduced to save time and money.

- Add this service to your Predictive Maintenance Program (PdM) to further protect your equipment and eliminate downtime.

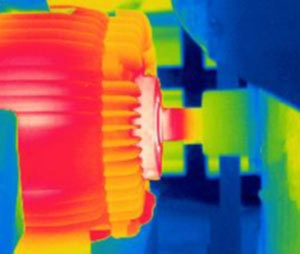

Thermal Imaging

Through thermal imaging, our team measures operating temperature of running equipment at multiple points at once, allowing us to identify a variety of potential problems. Loose connections can draw higher amps leading to failure. Thermal imaging can detect these before any damage is done to help you avoid downtime.

Installation/Removal

We can install or remove equipment at your location. Since we regularly work with electric motors and their repair, we have all the equipment necessary to get yours in and out without difficulty. Whether your motor needs to be taken off-site for repairs, you have a new motor in need of installation, or any other reason for transport, we’ve got you covered.

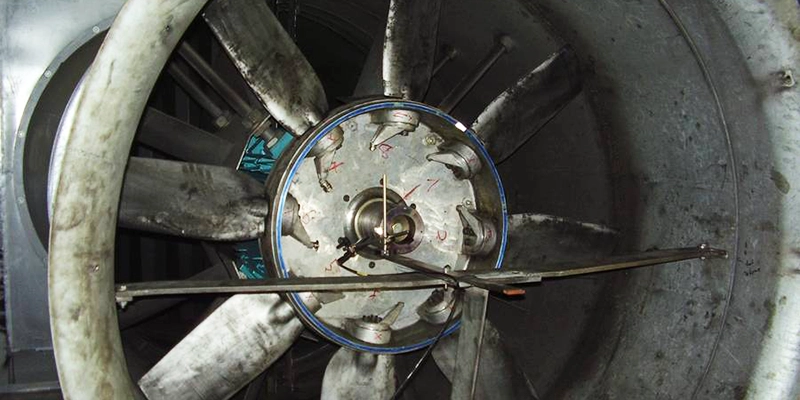

Onsite Balancing

Given time, rotating equipment will naturally go out of balance. Left unchecked, unbalancing can cause serious damage to your equipment and wear bearings prematurely. There is no need to disassemble the machine. Instead, our team can perform the field balancing work directly on the completely assembled machine.

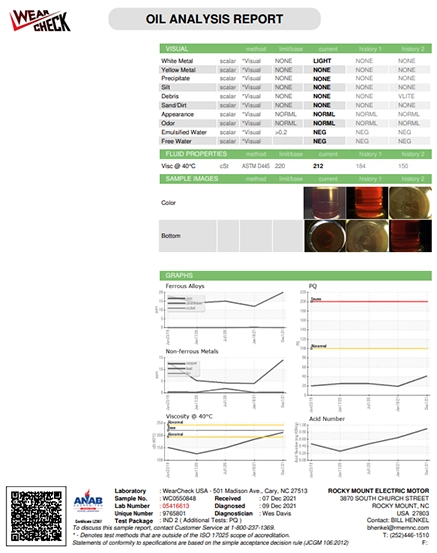

Oil Analysis

Oil analysis can detect signs of abnormal wear, such as metal particles, that indicate friction, corrosion, or fatigue in the machine components. It can also detect signs of contamination.

Onsite Diagnosis Analysis

Having an issue with your motor or motor control equipment and can’t quite determine which is the problem? We can test your motor on-site with our MA2 Motor Analyzer and determine if the motor is good or bad before you remove it. The unit performs 13 different electrical tests to definitively determine the health of the motor. If the motor is not the issue we can then troubleshoot what issues might be causing the problem such as VFD or wiring or motor controls.

We provide a variety of on-site electric motor services to assist our customers. Whether it’s aligning a new motor, balancing a fan, providing vibration analysis, or performing complete preventative maintenance analysis, we can assist you in many ways right on your site. Each service is performed to get your equipment quickly working again. This helps avoid as much downtime as possible. Let us help you keep your equipment running at optimum levels. Avoid costly breakdowns by scheduling your electric motor services! Give us a call today!