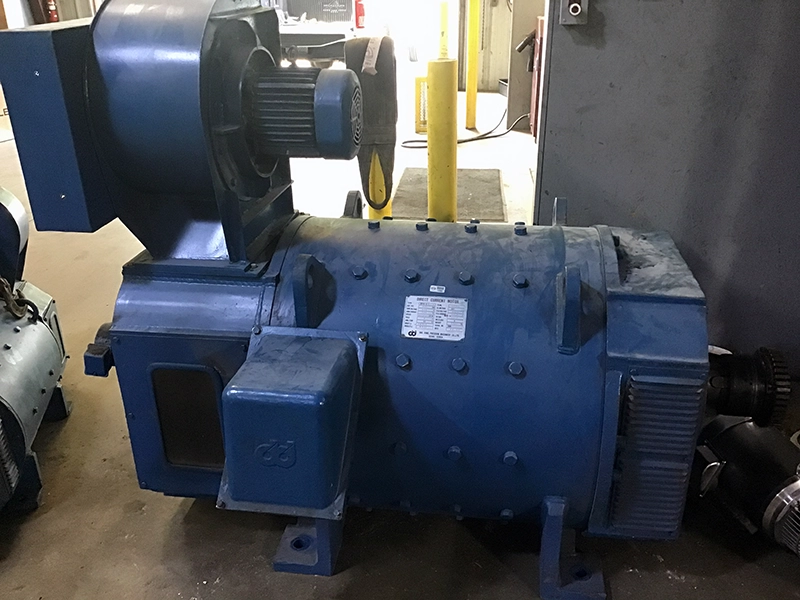

DC Motors

Gear Boxes

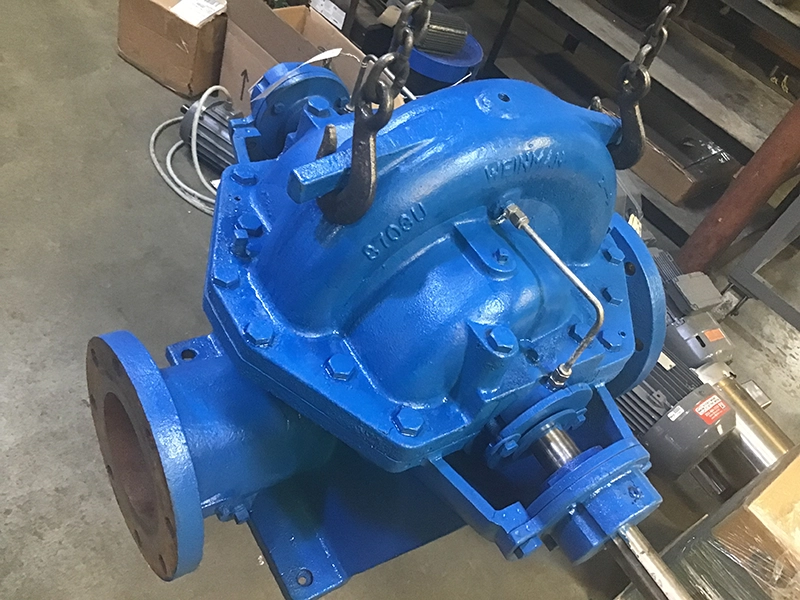

Pumps

Whatever electric motor repair services customers need, we work to find the best solution. We have our own in-house machine shop to repair end bells, journals, and shafts. We also dynamically balance rotors and other rotary equipment. Additionally, when working with your motor, we provide complete documentation of the testing performed on your motor. This includes initial test, core loss test, and surge test, to final analysis, including no load amps, vibration, and temperature.

One of the most critical capabilities of an electric motor repair facility is the ability to test-run remanufactured motors at full rated nameplate voltage. Testing running electric motors at full rated voltage is essential to accurately measure vibration levels and pinpoint mechanical problems that are not always detected at less than full voltage.

We perform detailed testing on all motors incoming and outgoing. Further, all testing data is recorded for future reference and baseline trending.

Our testing capabilities include up to 4,830 volts AC and 530 volts DC. We also provide core loss testing up to 1,250 HP and Surge and Hi-pot testing to 12,000 volts. This allows us to provide reliable testing for large motors not found in most electric motor repair shops.

Dynamic Balancing

Balancing fans and other rotary equipment.

Pick up and Delivery

Free pick up and delivery on normal weekly routes. Express delivery at nominal fee.

Rush Service

24/7/365 rush repair service

When our customers want electric motor repair, they know to trust our team with their valuable assets. All repairs begin with thorough documentation, testing, and inspection. This allows us to develop the best plan of action for getting it back in working order as quickly as possible.

At Rocky Mount Electric Motor, we use only the highest quality materials to rewind your motor. This means using inverter duty wire and class “H” insulation. Windings are laced at both ends and electrically tested prior to varnishing. Above all, these top-of-the-line materials and techniques allow us to ensure the motor is as good or better than received.

As part of our EASA Accreditation, you can be assured your motors are repaired in accordance with ANSI/EASA AR100 specifications. See more about Accreditation on our about or news page.

Schedule Your Electric Motor Repair Today!

RMEM follows “ANSI/EASA AR100-2015: Recommended Practice for the Repair of Rotating Electrical Apparatus” for all motor repairs we perform. This ensures your motor maintains premium efficiency. We are an EASA Accredited facility and can provide EASA Accredited repairs.